Geodesic Dome Struts: Flattening

|

|

|

|

| Cutting | Flattening | Drilling | Bending |

Why flatten?

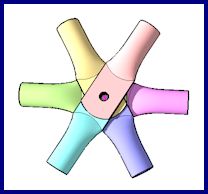

To attach all the struts of a vertex together with a bolt or many bolts.

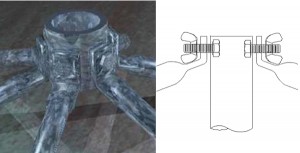

Each strut requires enough flat surface at each end to fit well together. Whether your struts connect directly to each other (as above), or you use other methods (as below), you still have to flatten enough area so they fit.

Flattened strut ends must be on the same plane

You can flatten the first strut end without worrying, but when you bend the second end, that’s where you must be careful. Each flattened section needs to be on the same plane as the other. To avoid this lay the first flattened end on a block. When you get to flattening the second strut end the alignment will already be set for you.

Equipment to flatten struts

|

|

|

|

| Sledge hammer | Vise | Arbor press | Hydraulic press |

- Sledge hammers and vises are the most accessible methods to flatten pipe such as EMT. They are also the most sloppy solutions. Because geodesic dome struts require precision in all steps from cutting to bending, an arbor press or a hydraulic press are the best ways to do the job. Both types offer stability and control over the material.

- An arbor press is the least expensive option, costing between $90-$250 for a 1-ton to 3-ton model. But avoid the low end ones as they may not last long enough to make all your dome struts. If you do want to use an arbor press, it makes sense to spend the extra money to get a higher-quality one with a greater pressure rating (such as a 5-ton model).

- A manual hydraulic press is a good compromise between an arbor press and a professional electric hydraulic press but it’s a slow option. The best compromise would be to find a manual hydraulic press that can also be connected to compressed air. You can find them for a few hundreds of dollars for a 10-ton press though beware of going for the low end models as you may want to justify your purchase by having it still useful in the future.

- An electric hydraulic press is something you find in a machine shop or a factory. They cost from a few thousands to many thousands of dollars. The biggest benefit is that the machine does the work for you. Place your strut, press the button and it’s done.

How to properly flatten struts

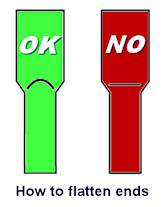

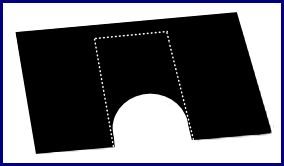

If you don’t flatten properly you take away from each strut’s structural strength. Look at the image below:

When you flatten as a straight line you make the struts more likely to warp under stress. But by creating an arched line you increase the structural integrity, strength of that strut to withstand warping.

So how do you flatten with an arched shape? With a die attached to a press.

As much as you may want to use a big hammer and whack the life out of the struts, it does not do a good job, and it certainly does not give an arched shape to the strut. Plus it’s a huge amount of energy.

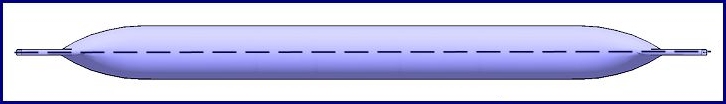

How much to flatten

As a rule of thumb, flatten 2 to 2 1/2″ from each end. This includes the extra length you need to add to drill bolt holes. The larger your struts are, the longer section you need to flatten.

If you use welded pipe

It is also possible that your pipe is welded. This means the material was rolled into tube form and then welded. If you do have welded pipe, make sure you flatten the conduit or pipe on the flat surfaces of the press.

Make a jig!

On my first 40-foot geodesic dome I used an electric hydraulic press. I had a metal block welded to the press frame, with a thin plate welded on top of it as a guide. When pressing all I had to do is have my pipe touch the guide plate and bring the press hammer down on the pipe. This way I always had the same length being flattened and I could push against the jig to minimize the pipe from moving.

Then someone misplaced the jig; I figured I had done so many I could eyeball it… Big mistake. When the press hammer came down, the pipe moved in different directions because there were no guides to hold it in place.