Polycarbonate panels

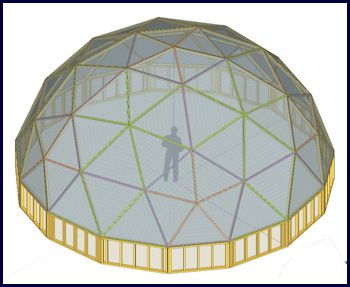

Polycarbonate panels for geodesic domes are primarily used for greenhouse structures. The two main justifications for this material is strength and durability. Many know it under the trade name Lexan® from General Electric. It is not to be confused with acrylic.

When deciding on how to cover a geodesic dome or a traditional greenhouse, the following factors are usually considered:

- Your budget

- How permanent you want your structure to be

- How you will use your structure.

Example #1: you build a greenhouse to grow fruits and vegetables from March to November. You don’t have the money for a polycarbonate covering. Here you may consider removing the covering until Spring. Your best option is probably to use a thick inexpensive polyethylene film. You will save on covering costs and not have to worry about reinforcing for snow loads.

Example #2: you are building a geodesic dome greenhouse from steel pipe. You want it to last a long time. In this scenario polycarbonate panels may not be suitable due to the difficulty to attach paneling to the structure. You would do better using a PVC coated canvas.

Example #3: you plan on building a timber geodesic dome greenhouse. You want it to last. In this case polycarbonate is probably your best option, especially since wood frames are very suitable for flat paneling on its service and sealing between panels will be simple to do.

As shown above, sometimes the simplest and least expensive option will do the trick. But for those requiring a long-lasting solution, please read on.

Polycarbonate 101

Polycarbonate panels are part of the group of thermoplastics, easy to work with, can be molded, and thermo-formed. The most common type of polycarbonate plastic is one made from Bisphenol A. The characteristics of polycarbonate are very similar to those of acrylic, but it’s stronger than acrylic.

Polycarbonate lets in light, more so than most types of glass. It is many times lighter than glass and virtually indestructible, with a high strength to weight ratio.

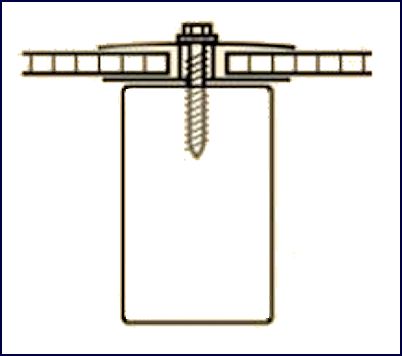

It can be held in place with screws, glued with epoxy and sealed with silicone, or held in place with support poles (ex: ice rinks). You can also weld it together.

Though it is highly resistant to shattering, polycarbonate sheeting may get scratched for a number of reasons These scratches can be removed using special polishes or cleaning products, though some may be permanent. Over time, excess scratching can cause the surface to appear dull, and may reduce visibility and light transmittance.

Technical properties

- Density of 1.20 g/cm3

- Usage range from -100°C to +135°C

- Melting point around 250°C

- Refractive index (diffusion) equal to 1.585 ± 0.001

- Light transmission index equal to 90% ± 1%

- Weak protection against ultraviolet (UV) light environment

Polycarbonate under different names

LEXAN® is the registered trademark for polycarbonate plastic manufactured by General Electric.

MERLON® is the registered trademark used by the Mobay Chemical Company.

MAKROLON® is the registered trademark for polycarbonate from Bayer, which is also referred to as “macrolon”.

PANLITE® is the registered trademark for polycarbonate plastic manufactured from Teijin Chemical Limited.

Polycarbonate vs. acrylic

Polycarbonate |

Acrylic |

| Virtually unbreakable (about 30 times more resistant than glass). More bendable, can be formed | More likely to chip, less impact resistance then Polycarbonate (still 10-24 times more resistant than glass) |

| Turns yellow under UV radiation | Will not yellow over time |

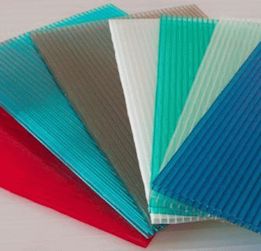

| Available in various colors including clear | Available in various colors including clear |

| Relatively expensive but less costly than glass | Less expensive |

| Poorer clarity, diffuses, light especially in multi layer panels | Less likely to scratch. Better clarity and can be restored to optical clarity |

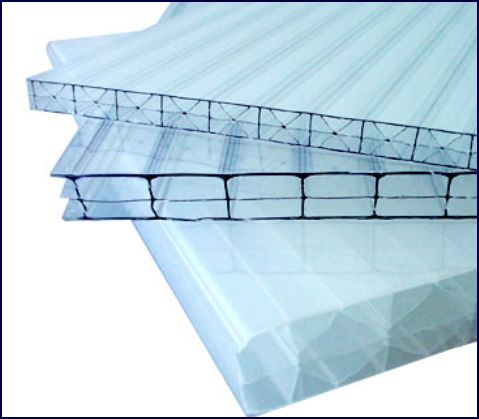

| Available in twinwall and triple-wall panels, beneficial in applications where insulation is important | Available mainly in sheet form |

Note: treated with UV stabilizers, you may get from 10 to 20 years of useful life, but this is at a greater cost.

Single, double, triple layer polycarbonate panels?

The most common form of panels are as flat “twin wall” panels, two flat polycarbonate panes separated by structural walls.

In single-layer form, polycarbonate has a transparency similar to that of glass. Multilayer panels usually include a rating in mm or fractions of an inch, indicating the space between panels. The greater the gap, the more efficient insulation the panels provide. The more layers, the more light is diffused.

Why use polycarbonate instead of glass?

Glass offers clarity, but with drawbacks. To be up to building code you may need to use safety glass around doors, off the floor, and when used overhead (as in a roof) it may be required to use annealed or windshield type glass, a type of glass that cracks easily and is very expensive.

And to have reasonable insulation you need two panels with air in between and a sealed frame to hold it together. Not only will this be very expensive, heavy, and require a stronger frame, the section seals will eventually fail. Have a warranty? Maybe not: in high moisture environments such as a greenhouse or around a pool the warranty often becomes null and void.

Plastics shrink in cold weather: use channels

Both polycarbonate and acrylic will shrink as the temperature drops.

The shrink rate of either material varies on factors such as the manufacturing process and raw materials used, but for a typical greenhouse, the shrinkage will be noticeable. To remedy this, the solution is to use “channels” to hold the panels in place while solving the shrinking issue.

Panels are slipped in between 2 channels. The fit is snug with just a slight amount of wiggle room. In situations where the temperature is low, such as in winter, the long lips of the channel ensure that the panel will not fall. The result is that there is no stress on the panel and the greenhouse remains watertight.

When glazing a geodesic greenhouse, H channels are on each side of every panel and each side will need to be shorter to accommodate the space used for the channel.