Greenhouse Ventilation

Greenhouse ventilation involves removing air from inside the greenhouse and replacing it with outside air. The ventilation may be (1) natural–caused by wind and temperature forces–or (2) mechanical–accomplished by using fans. The purposes of ventilation are to control high temperatures during the summer caused by the influx of solar radiation, to maintain relative humidity at acceptable levels during winter, to provide uniform air flow throughout the entire greenhouse, and to maintain acceptable levels of gas concentration in the greenhouse. Ventilation systems for greenhouses must be considered for three climatic conditions that occur during the year–winter, summer, and spring-fall.

WINTER VENTILATION

A heating system with adequate capacity is needed in the winter to maintain environmental conditions inside the greenhouse conducive for plant growth and development. Even during the coldest part of the winter, when the heating system is running at full capacity, some ventilation is still required in the greenhouse. Fresh, outside air must be ventilated into the greenhouse to remove the warm, moisture-laden air from within the greenhouse. If moist air within the greenhouse is not removed, high humidities and excessive condensation will occur. Studies have shown that humidities over 90% foster rapid development of leaf mold and fruit and stem rot.

Problems with infection of tomatoes with leaf mold start occurring when humidities exceed 80%, but below 70%, problems with infection are slight. Economic problems associated with condensation in greenhouses are fungus diseases, difficulty in maintaining a clean greenhouse, more rapid deterioration of structural components, and damp, uncomfortable environmental conditions for the workers.

Condensation occurs when warm, humid air in the greenhouse comes into contact with a cold surface, such as glass, fiberglass, plastic, or structural members. The air in contact with the cold surface is cooled to the temperature of the surface. If the surface temperature is below the dewpoint temperature of the air, then water vapor in the air will condense onto the surface. For example, condensation occurs if air in a greenhouse at 70° F Greenhouse Ventilation 2 and 70% relative humidity comes in contact with a surface that is 60° F or colder.

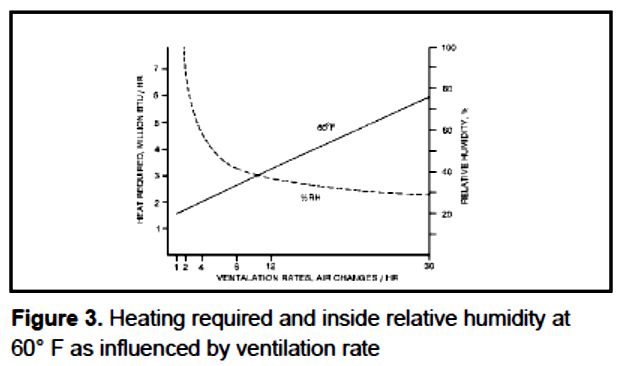

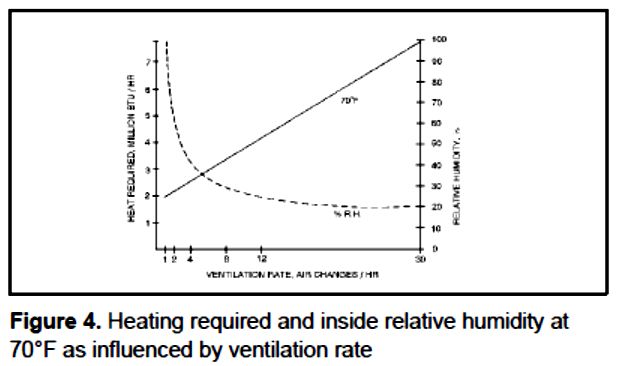

Exhausting moist air and replacing it with heated outside air is effective in eliminating condensation and other problems resulting from high humidities. Whenever ventilation rates are increased in the winter, the heating requirements also increase. Consequently, it is necessary to determine a ventilation rate that will maintain humidities below the damaging level and, at the same time, keep the heating requirements as low as possible. Ventilation requirements of greenhouses in winter are generally on the order of two to three air changes per hour. The higher the inside temperature in the greenhouse, the lower the air exchange rate that is required to maintain humidities below the damaging level. However, in no circumstances should a ventilation rate of less than two air changes per hour be used.

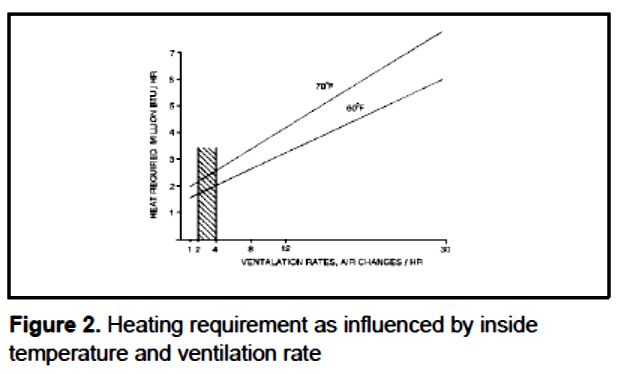

Besides controlling humidity, this minimum ventilation rate is required to remove any gases of combustion that may be present as a result of leakages around the heater and ducting when a direct-fired heating system is used. Figure 2 presents the heating requirements of the fiberglass greenhouse shown in Figure 1 for two different inside air temperatures when the outside conditions are 30° F and 80% RH. The heating requirement when the greenhouse is maintained at 60° F is about 20% less than the heating required to maintain 70° F. At 60° F however, the ventilation rate necessary to maintain humidities at a reasonable level is three air changes per hour.

Figure 3 and Figure 4 show the inside relative humidities that would result as a function of the different winter ventilation rates for 60° F and 70° F. Obviously, there is no benefit whatever in ventilating above four air changes per hour in the winter. The result would be excessive heating requirements and perhaps some damage to the plants because of low relative humidity.

SUMMER VENTILATION

The main purpose of a ventilation system in a greenhouse during the summer is to prevent the air temperature inside the greenhouse from rising too high above the outside air temperature. The reason for the higher air temperature inside the greenhouse is because of the large influx of solar radiation through the greenhouse glazing material. The ventilation system must effectively move air directly through the crop and over the soil to prevent excessive temperature buildups around the plants. A generally accepted minimum ventilation rate for temperature control in the summer is one air change per minute.

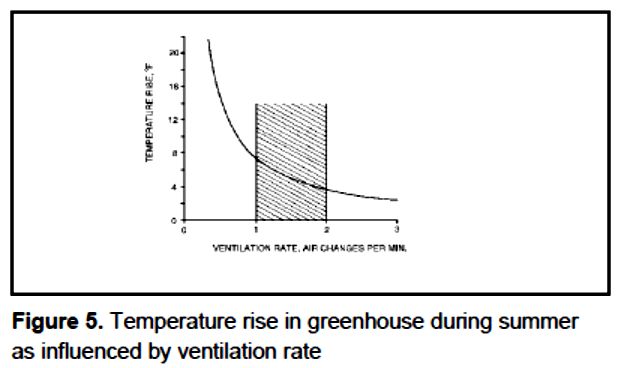

The resulting temperature increases (inside temperature minus outside temperature) on a clear summer day for the greenhouse shown in Figure 1 are presented in Figure 5. The ventilation rates range from one air change every three minutes to three air changes per minute. As ventilation rates increase, the temperature difference between inside and outside air decreases. But the disadvantage of increased ventilation rate is the increased cost for fans and accessories, as well as increased operating costs.

Regardless of how high the ventilation rate in a greenhouse is in the summer, the inside air temperature during the day will never be as low as the outside air temperature. If one is interested in maintaining an inside air temperature below outside air temperature, then evaporative cooling or some other means of conditioning the air must be used.

Filtering out a portion of the incident solar radiation is very effective in reducing the inside air temperature of a greenhouse. The filtering can be accomplished by using shade cloth stretched eave to eave within the greenhouse, painting the exterior surfaces of the glazing materials, selecting glazing materials with a low transmission coefficient, or sprinkling the roof with a fine mist of water, for example.

The shade cloth stretched from eave to eave separates the hot air that accumulates in the ridges from the crop region. Thus the air in the plant region will be cooler and the overall efficiency of the ventilation system will be increased. Filtering solar radiation to decrease heat load on a greenhouse should only be attempted in those operations involving plants that do not require “full sun.”

SPRING-FALL VENTILATION

The recommended ventilation rates for the spring-fall seasonal periods will be somewhere between rates required for summer temperature control and those required for winter-humidity control. The spring-fall periods are characterized by some times that are relatively cool and cloudy and other times that are warm and sunny. No special provisions are necessary for maintaining ventilation rates during this period except for the temperature and humidity controls that will determine the amount of ventilation necessary.

DETERMINING VENTILATION VOLUME RATES

In the preceding discussion, ventilation rates were expressed as a minimum ventilation rate of two air changes per hour in winter and a minimum summer ventilation rate of one air change per minute. To select fans as part of a ventilation system, one must know the total volume of air to be moved by the ventilation system. Volume of air to be moved is calculated from air changes per hour or minute.

One air change is equivalent to the volume of the greenhouse. For example, the greenhouse indicated in Figure 1 has a volume of 254,448 cubic feet. Therefore, one air change per minute would correspond to a ventilation flow rate of 254,448 cubic feet per minute. In winter when the minimum ventilation rate is stated as two air changes per hour, the volume flow rate of air would then be 508,896 cubic feet per hour (254,448 cubic feet per air change x 2 air changes per hour). Dividing the previous answer by 60 minutes per hour then yields an air flow rate of 8,482 cubic feet per minute.

The volume of a specific greenhouse is calculated as the product of the area of one end wall times the length of the greenhouse. In the example in Figure 1, one end wall area of the greenhouse is 684 square feet. The length is 372 feet. The product, 684 square feet times 372 feet equals 254,448 cubic feet. In calculating the area of an end wall of a greenhouse, the following relationships may be helpful:

1. Area of a rectangle is base times height.

2. Area of a triangle is base times height, divided by 2.

Select only fans rated in accordance with AMCA (Air Moving and Conditioning Association) Standards. This rating specifies the volume capacity of a fan versus static pressure resistance to air flow Greenhouse Ventilation 4 measured in inches of water pressure. For ventilation in most greenhouses, the fans should move the desired air volume rate against a static pressure of 1/8-inch water. When evaporative cooling pads are used, information must be obtained from the supplier or manufacturer on the expected static resistance. Topics on fan theory, selection, testing, noise, inspection and care, and fan motor selection are presented in the IFAS Extension Fact Sheet AE-12, “Fans for Greenhouses.”

AIR DISTRIBUTION WITHIN GREENHOUSES

Air movement is important to plant growth within greenhouses. Continuous positive air movement within greenhouses is highly desirable since it equalizes temperature, carbon dioxide, and humidity levels within the greenhouse. Through improved environmental conditions, healthier plants can be grown and problems with disease associated with high humidity or “stale air” lessened. Though the optimum air velocity has never been thoroughly investigated, it is suggested that a minimum velocity of 40 feet per minute should be provided. Below this level, air flow is unpredictable, and mixing throughout the greenhouse area will not be achieved.

A velocity of 40 feet per minute will cause slight leaf movement with plants having long branched leaves. For effective uniform air circulation, a mechanical ventilation system is necessary. A horizontal convection system, where all the air in the house is moved in a horizontal, circular pattern, is recommended. Such a system is simple in concept and easily installed. A perforated polyethylene sleeve system or sidewall ventilation-recirculation system is also satisfactory. Both of these systems are more difficult to install properly, but when correctly installed and balanced, they are quite effective in developing uniform and desirable air circulation patterns. These systems have the advantage that the system can effectively be used for heat distribution as well as air circulation. The perforated sleeve system is also widely used for the introduction of ventilation air in the winter.

NATURAL VENTILATION

Many older greenhouses depend on natural ventilation for air movement. However, with increased concern about the high cost of energy required to operate greenhouses today, increased emphasis is again being placed on natural ventilation systems for greenhouses. In greenhouses employing natural ventilation systems, sidewall vents and ridge vents continuous for the full length of the building can be opened as far as desired to allow air to move through the house.

To be ventilated satisfactorily, the house must have both sidewall and ridge vents. If a house has only side vents, then it can only be ventilated during periods of wind movement outside. Using ridge vents and side vents permits the greenhouse to be vented by both wind pressure and thermal gradients. Thermal gradients generally are created within the greenhouse by solar energy heating the materials inside, which in turn heat the air.

As air is heated, it becomes lighter and rises through the ridge vents, with the makeup air coming from outside through the sidewall vents. If sidewall and ridge vents are properly sized, quite satisfactory ventilation rates can be achieved with some degree of temperature control. A natural ventilation system will not be as dependable or satisfactory as a mechanical ventilation system in terms of providing continuous, uniform greenhouse ventilation.

Some newly-designed greenhouses with natural ventilation systems are capable of achieving a high degree of environmental modification for increased plant production. However, for those plant species that require air temperatures lower than outside air temperature, evaporative cooling must be used. Mechanical ventilation is an integral part of any evaporative cooling system.

The real advantages of a natural ventilation system are related to economics: (1) no expenses for ventilation equipment, electrical operation, and maintenance and (2) no problems created by “brown-outs” or “black-outs,” caused by storms or insufficient generation capabilities. As the cost of energy and the likelihood of power failures increase, the natural ventilation systems become more desirable.

D. E . Buffington, R. A. Bucklin, R. W. Henley and D. B. McConnell2

1. This document is AE-10, one of a series of the Agricultural and Biological Engineering Department, Florida Cooperative Extension Service, Institute of

Food and Agricultural Sciences, University of Florida. Original publication date January, 1993. Reviewed July 2002 and April 2010. Visit the EDIS Web

site at http://edis.ifas.ufl.edu.

2. Dennis E. Buffington, professor, department head, Agricultural and Biological Engineering Department, Pennsylvania State University, University Park PA

16802 (former professor, Agricultural Engineering Department, University of Florida, Gainesville FL 32611); Ray A. Bucklin, associate professor,

Agricultural Engineering Department; Richard W. Henley, professor, Central Florida Research and Education Center (CFREC), Apopka; Dennis B.

McConnell, professor, Environmental Horticulture Department; Cooperative Extension Service, Institute of Food and Agricultural Sciences, University of

Florida, Gainesville FL 32611.