Bamboo as a building material

Introduction

Bamboo species Guadua angustifolia

Building with bamboo looks back on an ancient tradition in the regions in which plant grows in abundance, such as South America, Africa and, in particular, in South-East-Asia. Bamboo is one of the oldest construction materials.

Bamboo as plant

Botanical classification

Several bamboo species

In 1778 Carl von Linné introduced the description bamboo into sience based on the Indian word “Mambu” or “Bambu”. The family of the gramineae (grasses) incorporates the subfamily of the bamboos. The gramineae also comprise the rice, corn and sugar cane. There are existing 500 different species of bamboo with partial some hundred subspecies.

The term bamboo describes all tree- or bush-like grasses having a durable woody or branched stem. The lignifying cell structure of the bamboo tissue and its technological properties are very similar to the wood tissue proper. Bamboo may therefore also be termed wood. Contrary to wood, the bamboo have a hard outer surface and is soft inside. Characterised by the type of rhizome and the formation of upright canes there are three main groups of bamboo.

The first group is called monopodial bamboos. They form long and thin extensions of the rhizome whose buds produce single shoots are regular intervals. The sympodial bamboos constitute the second group. They have short, thick root stocks the tips of which produce the canes. The third group is called climbing bamboos. They can grow very irregularly and may form impenetrable thickets.

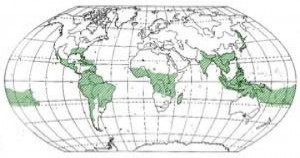

Geographical distribution, climatic and soil conditions

Geographical distribution

The main area of distribution are the tropics, in particular, South-East-Asia. Bamboo grow at sealevel and can be found at altitudes of up to 3800m.

Most bamboo species grow at temperatures from -28°C to +50°C. Bamboos grow mainly on sandy loam to loamy clay soils. They prefer well drained soils but grow also in wet and even marshy locations. They do not tolerate saline soils.

Growth

The growth pattern of the bamboos is a singular combination of grass, leaf-bearing tree and palm. Like the grasses they have tubular blades, lancet-shaped cover leaves and panicular flowers and from a subterranean rootstock branch extensively to form dense to loose bushes. The following characteristics distinguish bamboos from grasses: the longevity of their canes, their branching and the lignification. Like leaf-bearing trees they increase their crown every year by throwing out new branches and also shed their leaves each year.

The growth pattern of the trunk is similar to that of the palm tree. Emerging with its definitive circumference from the soil without increasing in diameter later. The species “Guadua angustifolia” will reach length of up to 20 – 25 m with a diameter of 12 cm.

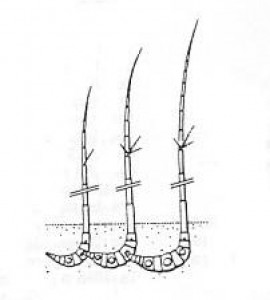

Root

Monopodial species

Bamboo has durable root stocks, the rhizomes. After a seedling has produced the first rhizome, the differentiated rhizome system will begin to develop. Its circumferential and longitudinal growth increases annually. It is only after twelve and more years that canes of full thickness and height will be produced. According to the type of branching of the rhizomes the main group of the bamboos is called monopodial, whereas the other group is called sympodial.

Sympodial species

The monopodial species grow horizontally over large distances. A rhizome stolon will grow in length by 1 – 6 m per annum with an average life span of ten years. At irregular intervals the lateral buds produce single cane stems from which new canes grow upwards. These species can be found in subtropical regions with a temperate climate.

The sympodial species develop horizontally over short distances growing in a circular spreading pattern by 1 -3 rhizome bulbs per original rhizome.

Their points bend upwards and allow the new cane to mature. These species are characteristic of the tropics. Several root systems can penetrate and overlay each other, resulting in cumulative root stolon. The bamboo root network thus forms a supremely effective protection against erosion, it delays the draining and soaking-away of rain water and thus serves as a moisture store.

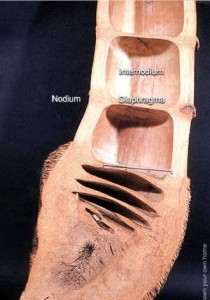

Cane

Segments of the cane

The basic form of the bamboo plant consists of a branch system of segmented axes. There is no main axis for a central stem; each axis branches off another. There is a regular succession of nodes and segments in rhizomes, canes and branches. The shape of the canes vary between straight and exactly vertical, overhanging or zig-zagged, curved or creeping.

Bamboo is distinguished by its longitudinal growth. There is no other plant which grows as fast as bamboo. Some species of bamboo grow 5cm per hour. The species “Guadua angustifolia” grow

12cm per day.

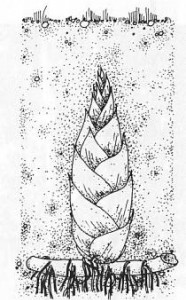

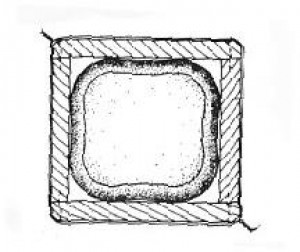

Section through a bamboo rhizome

The canes of bamboo consists of nodes, segments and diaphragms. At first the canes appear as small buds at the nodes of the rootstock. There they grow for several years until they emerge from the soil in the shape of short, thick, conical shoots surrounded by sheath leaves. From that point the bamboo shoot will develop into a cane at enormous speed. Within a year at the latest it will reach its full size and the sheath leaves dropped completely. The average length of the canes amount 8 -15 m with a diameter of 5 – 12 cm and a wall thickness of 10 mm.

Also the cane diameter remains unchanged as long as the cane stands. For this reason the diameter of the cane does not indicate its age. The age is judged by the sound of the cane and the appearance of its surface.

Each shoot pushing out of the soil contains already in miniature all the nodes, segments and diaphragms which the fully grown cane will posses later. The segment closest to the ground increases in size first, and the one at the top last. The numbers and lengths of the segments per cane differ according to species. Smaller species have canes consisting of 15 – 20 segments, whereas larger species can have up to 55 segments. The segmental length increases from the base of the cane to its middle and decreases again towards the top. Most bamboo species have an average segmental length of 35cm. In most cases the interior of the cane remains hollow. Species with a solid cross section are rare. Frequently the segments at the top become solid.

Bamboo bud with sheath leaves

The nodes provide the insertion points of the shed sheath leaves. As a form of reinforcement they increase the resistance of the cane against splitting and buckling. Bamboo canes have a circular cross-section and are axially slightly conically tapered. From the base to the top they taper very gradually. Shorter canes taper more strongly than the longer ones. For this reason the long canes are preferred for building purposes. Not only the diameter of the bamboo canes decreases with increasing height but also the wall thickness.

After about the first three years of growth the canes start lignifying and silicate slowly. It is only then that they become useful as structural timber. The bamboo skin contains a high proportion of silicate acid. Because of the hard silicate layer of the outer surface, bamboo is highly resistant against chemical, animal and mechanical exposure.

The surface of the young cane is green, later becoming yellowish, sometimes brown to black and either of uniform color. The surface is mat or shiny. Some species are distinguished by a longitudinal stripe pattern of different colors and widths.

Branches and leaves

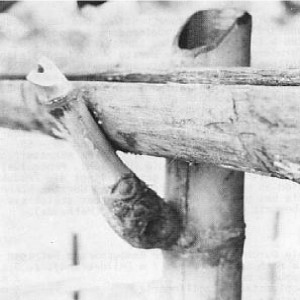

Branch serving as support

The cane remain free of branches for a period of not more than year until develops its full height. This branching process proceeds from the top downwards and, in few species, may extend to the base of the cane.

The branch bases sprout from the nodal protuberances. They have a strong connection between the diaphragm and the nodal bead. The branch forks are suitable as supports for lighter structures.

The branches carry stemmed grass leaves which can be of various widths. In general one can say that the taller the bamboo cane, the smaller the leaves. Like our leaf-bearing trees, the bamboo sheds its leaves every year but with the following difference: the new leaves start growing without delay. As infill for cavity flooring or walls they provide a good insulating material. Because of its low weight the load-bearing structural elements are only subjected to minimal addition loads. Long and broad bamboo leaves are also used for roofing.

Bamboo cane with branches and leaves

Bamboo flower, fruit and maturity

Bamboo flowers

Usually bamboos flower only once in their lifetime and die after bearing fruit. Some species can also flower annually without dying. During the flowering period the canes shed their leaves. After this no new leaves are formed. The smaller species flower after approximately 3 to 4 years, whereas larger species can flower after 20 to 80 and in certain cases after 120 years. The flowering pattern may be divided into sporadic and mass flowering.

With sporadic flowering the flowers appear only in particular clusters and on isolated canes within that clusters. With mass flowering all the clusters are in flower simultaneously. This flowering can extend over large areas and even through entire countries.

The individual flowers are formed from ears and panicles and measure only a few millimeters. The bamboos normally flower in the last months of a year and seeds mature at the beginning of the next year. At the start of the rainy season, after the rispening of the seeds, the first new bamboo plants can be seen on the ground. These are 10 to 50 cm high tin canes which are thicker and longer than the previous ones are added. The reason for this growth in size is the strengthening of the rhizomes. The rhizomes are fully developed only after many years and can then produce canes of

the full height and diameter.

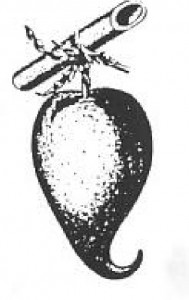

Bamboo fruit

All bamboo fruits are edible. The majority of bamboo species produce ripe fruits only rarely. Most fruits falls to the ground before ripening. The ability of the seeds to germinate is very low. To cultivate artificially the bamboo is surer and much quicker consequently. Bamboo can bee cultivated by division, from cuttings or by layerings.

Life span

The canes die and fall to the ground only a few weeks after the production of flowers and fruits. Frequently their rhizomes are exhausted and also die. With the large species the life span is determined by the flowering period which can be up to 100 years. In the latter case the flowering period and the life span are not equal because the plant can flower frequently without dying.

Harvesting, storage and drying

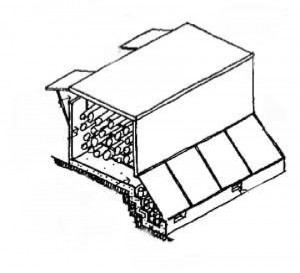

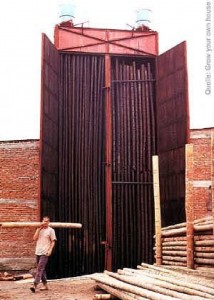

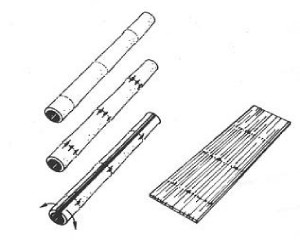

Frame for storage

At intervals of two to four years up to 30 % of the mature poles are removed from the cluster. The remaining canes not only support the young shoots but also maintain the full power of the rhizomes. Two to five year old bamboo poles are considered most suitable for building and other purposes.

The correct seasons for felling are autumn and winter in the subtropics and the dry season in the tropics. This reduce attack by beetles because the insects are less active. Felling is best carried out using a machete or similar tool. After felling the branches have to be carefully removed so that the outer skin of the cane is not damaged. Bamboo poles should be stored horizontally and frequently supported so that they can neither sag nor bend. They should be protected aigainst sun, rain and soil moisture.

There are two possibilities for drying the bamboo canes. The air-drying process in frames with good air circulation takes 6 – 12 weeks. The kiln-drying process takes only 2 – 3 weeks. But some species of Bamboo do not tolerate quick drying. The bark develops cracks orthepoles split axially.

Bamboo preservation in general

Beetle “Lyctidae”

With increasing moisture of the bamboo increases the danger, that the bamboo will be attacked by animals or vegetable pests like fungi, beetles and termites. So the best time for harvesting is the drier and cooler season when the insects are less active. The pests can attack living bamboo canes and felled ones and can perforate them to such an extend that it becomes unusuable.

Passive methods

Covered bridge from Jörg Stamm

Simple constructive measures like lifting up the pillars or an outjutting roof can help to extend the life time of the bamboo distinctly.

Active methods

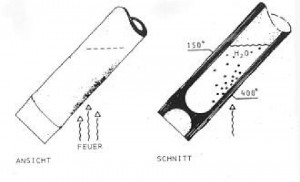

Oven to smoke bamboo

Smoking: Another possibility to preserve the bamboo is smoking it in its own resin. The smoke makes the rind unpalatable to insects which therefore decline the bamboo.

Heating: The canes are heatted in kilns to ca. 150°C for a short time, so the structure of the outer zone changes and becomes more resistant against insects. The poles can crack up easily.

When you cook bamboo, the starch and nutrient content will be reduced. The Problem is to find a container that is big enough to cook the canes in it.

Immersion: Freshly cut canes are immersed in water for 4-12 weeks. The nourishment for insects (starch and sugar) is removed. Streams are more suitable than stagnant ponds. Saltwater is not suitable, because the salt will stay in the bamboo and can bring moisture and fungi into the canes.

Impregnating coatings: Coatings with borax are ecological and widely used. In addition, lime slurries, rangoo oil or slurries from lime or cow dung are also used. Using insectices is ecological not acceptable. These are kerosene, DDT, PCP and others.

Aim

These methods prevent the invasion of pests during changing the surface of the bamboo or remove the nourishment of the insects. To protect the bamboo from fungi and mold, the moisture must be kept away.

To preservate the bamboo inside of the pole, all diaphragmas have to be perforated or all segments drilled. The life time of not-preservated bamboo will be approx. 2 1/2 years, of preserved bamboo approx. 10 years.

Properties

Fire resistance of a bamboo cane filled with water

Tensile strength:

The fibers of the bamboo run axial. In the outer zone are highly elastic vascular bundle, that have a high tensile strenght. The tensile strength of these fibers is higher than that of steel, but its not possible to construct connections that can transfer these tensile strengths.

Shrinking: bamboo shrinks more than wood when it loses water. The canes can tear apart at the nodes. Bamboo shrinks in the cross section ca. 10-16 %, in the wall thickness ca. 15-17 %.

Fire resistance: the fire resistance is very good because of the high content of silicate acid. Filled up with water, it can stand a temperature of 400° C while the water cooks inside.

Elasticity: the enormous elasticity of bamboo makes it to a very good building material for earth-quake endangered areas. Another advantage of bamboo is its low weight. It can be transported and worked easily, the use of cranes is mostly unnecessary.

The working of bamboo

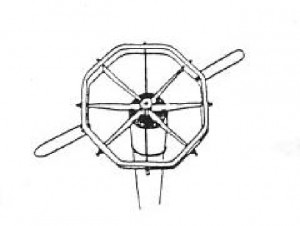

Splitting of a bamboo cane

Bamboo can be worked with the simplest tools wich must be especially sharp because of the highly silicified outer zone. Tool wear is considerably high.

Recommendable methods:

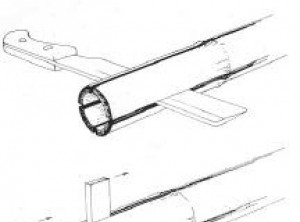

Splitting: very easy as long as you work along the cane axis. The cane is split in halves and quarters and the driven apart by a wedge. It can also be split with a knife frame into four or eight segments.

Cutting with a machete-type or knife used for:

- cutting.

- Sawing

- Scorch drilling

Splitting bamboo with a knife frame

Producing bamboo planks

By means of splitting you get halved canes, strips and battens. To get planks, all the nodes are smashed and the wall of the pole is split over its entire length and forced open until the wall of the pole lies flat.

Up to the age of 18 months, the canes can be peeled. The strips can be used as ties or be woven to make strings and ropes.

Bamboo being forced to grow in a box

Shaping: Bamboo which grows in a box gets a square shape. So it can be better used for connections.

Bamboo shaped under heat

Bending: Freshly cut, bamboo can be bent and will keep this shape after drying. When heated above 150° C, bamboo keeps its shape after it goes cold.

Treatment of the surface

This information about bleaching and dyeing is determined for small parts for kite-constructions. Bleaching and dyeing possibly can change the structure of the bamboo that far, it can´t support enough weight. Nevertheless these methods should be introduced.

Bleaching:

Bleaching in hydrogen peroxide removes traces of resin or wax. If it stays in it too long, the bamboo will get perished.

Dyeing:

Every country has developed its own traditional method of dyeing. In principle:

1. Remove the wax, otherwise the colour can´t penetrate into the bamboo.

2. Bleach befor dyeing, so the colour will become more regular.

3. After dyeing, fix the color in a solution of vinegar.

Other methods:

In Japan, the surface will be peeled off, hydrochloric acid is put on the bamboo and the canes are put in an oven. The canes get a brown colour. treating the canes with copper sulfate will give a green color to the bamboo and protects it from mould.

These methods only dye the surface of the bamboo. To get a through and through dyeing, the bamboo can be carbonized. The bamboo is put into a boiler and is incubated with a pressure of 5 kg/cm³ and a temperature of 150° C for 20-30 min. After that, the bamboo will be brown through and through.

Scopes

Bamboo material offers a surprisingly large number of applications and uses. Bamboo as a building material in the bamboo architecture is using for several constructions. In the following some of these constructions will be represented.

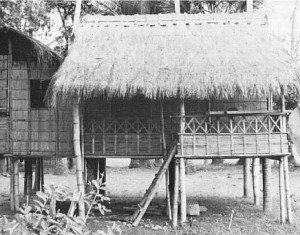

Bamboo houses

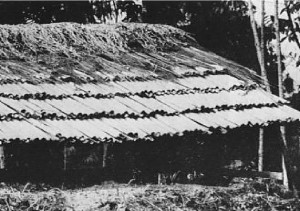

Bamboo house as a skeletal building

Bamboo houses are without exception skeletal buildings having raised floors with main posts which are anchored in the ground. Typical bamboo elements are canes, halved canes, laths, beading, bamboo boards and rope ties. This way of construction offers the following advantages: pre-fabrication, simple assembly, simple replacement of structural parts; the bamboo elements can be easily dismantled and reused.

Posts, battens, rails, purlins and rafters from the longitudinal and transversal bamboo framework. Normal cane diameters are 5 – 10 cm. Walls, floors and roof are linings rather than stiffening

elements of the non-rigid framework because braces and diagonal stays are absent in those planes. The structural safety of the skeletal structure is almost exclusively provided by the posts anchored in the ground. The only vertical and horizontal forces acting on the structure are wind pressure, roof moisture, live loads and dead weight.

The framing is connected by articulated joints. All the framing bars can slightly move in relation to one another. Although each part is able to transfer all axial and transversal forces. Rigid connections or joints are very rarely used. Above all the structure must be able to withstand dynamic loads, for example wind gusts.

The building materials as well as the structure have a high elasticity and low mass. This is the reason, why this houses are secure from an earthquake.

Roofing

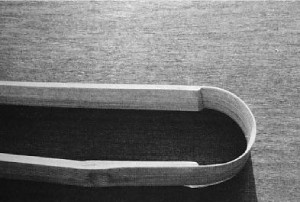

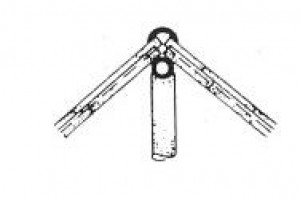

Halved bamboo canes in Roman tile fashion

The simplest roof covering is formed by bamboo shingles which are as long as the rafters. To produce the shingles the bamboo canes are halved along their length and the diaphragms are removed. They are threaded to the ridge and placed in Roman tile fashion. These shingles are nit fixed at the eaves. They are held in position by their own weight.

Double layers of bamboo shingles

The next roof covering is being composed of double layers of shingles. Each row of shingles is threaded onto a strip and tied to a pole with simultaneously functions as purlin and roof batten. Therefore the purlins are arranged in pairs.

The multi-layered shingle roofing is the most expensive and heaviest type of roofing. Instead of a roof covering one can call this a roof wall having a thickness of up to one metre. The rows of shingles are fixed to the roof battens by an inserted key which prevents them from sliding off. Layer is placed upon layer up to the ridge. The roof structure is made of solid timber.

The lancet shingle roofing is very expensive. These are cut from bamboo laths in the length of the segments. On the back of the lancet shingle a tongue is split away from the bark layer and this tongue is inserted between pairs of roof battens. The shingles are placed with their concave side upwards. Because of the better drainage the shingle should contain no nodes outside the batten area.

Lancet shingles

In comparison with covering consisting of stranded palm leaves the bamboo leaf cover has some disadvantages. The lancet shape, the fanning-out of the bunches and the twisting of the leafs necessitate more layers of leaf bundles, a steeper roof pitch and more solid substructure. But these roofing is not rain proof after longer periods of rain. Roofs with shingles made from bamboo shavings have a thick layer and are exceptionally wind and rain proof. These shingles look like brushes with long bristles. They are bent over a batten and sewn together.

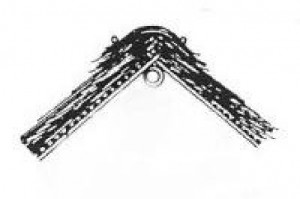

bamboo cane on the ridge

When using organic materials for roofing, the ridge is the most exposed part of the rain-proof layer. With hard roofing materials a half of a large diameter bamboo cane is placed on the ridge joint with the convex side up.

Palm leaves on the ridge

With soft materials the parting at the ridge has to be covered with an especially carefully applied layer of material. This layer is secured by bars against being lifted off by the wind.

The roof surfaces are protected against the wind by wide-mesh latices of bamboo strips. At the verges securing boards made from halved canes are tied into the rafters with inserted keys. Bamboo houses usually have no gutters. An exception are gutter-type purlins, whose water-catching function is, however, only secondary.

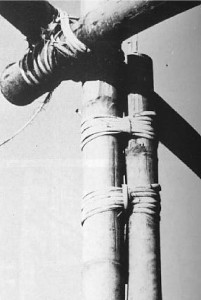

Scaffoldings

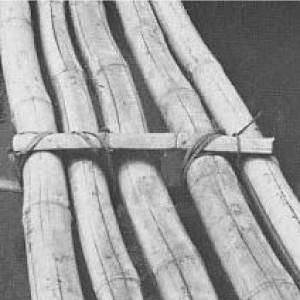

Bamboo canes used for scaffoldings

Because of the favorable relationship between load-bearing capacity and weight, bamboo can be used for the construction of save scaffoldings even for very tall buildings.Lashed cane extension Even at their connections the canes are not treated in any way. Only lashed joints are used. The cane extension is carried out by lashing the cane ends together with several ties. The ties are arranged in such a way that a force acting vertically downwards wedges the nodes in the lashing. With larger cane diameters the friction can be increased by tightening the rope between the canes. The vertical and horizontal canes used for scaffolding are almost exclusively joined using soft lashing. This technique has the great advantage that the joints can be re-tensioned to the right degree without difficulty and also quickly released again.

Lashed cane extension

Footbridges and bridges

Footbridge without surface

Footbridges and bridges are also constructed from bamboo material. Since bamboo is much more elastic than solid timber, its use requires particular constructional measures which limit vibration, bending and twisting. Footbridges and bridges are structures which are exposed to the weather, if indeed they are covered. For this reason their life span is only one third of that of house structures.

Bamboo as a building material for bridges has applications ranging from a few bamboo poles placed across a ditch to the twin suspended framed truss spanning a 30 – 50 m wide river. The following examples presenting a review of the possibilities with a short description.

Tied battens hold the poles together and act as a load distributor so that the load on a single pole is transferred to its neighbour. The ends of the poles are pinned to the ground. They are secured against turning and displacing.

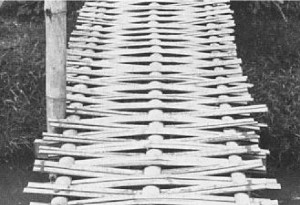

Footbridge with surface

Footbridge with surface of woven batten. The layer of poles has differing spacings. The woven battens provide rigidity and distribute the load. Piles serve as intermediate supports and also as posts for the handrail.

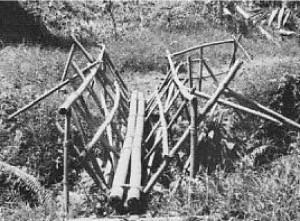

Footbridge with tied rail

Footbridge of cane bundle with tied rail. In this example a bundle of five bamboo poles forms the load-bearing beam. The lashing consist of strips of bamboo bark. The posts are tieddiagonally between the beams and hold these in place. The ends of the handrails are supported by vertical posts. In the middle of the bridge the handrails are also braced by long canes anchored in the embankement to steady the V-shape against toppling.

Bamboo bridge with intermediate posts

Bamboo bridge with intermediate posts in the river bed. When using many piles, the spans are usually kept below 2 m. The piles or posts form bundles ot two or three posts of which only one continues above the bridge platform to carry the handrail. Longitudinally and transversely they are stiffened by diagonal braces. The bridge floor is covered with woven battens which are held on the floor joists by bars located in the edges. Lateral sliding of this covering is prevented by the bridge posts.

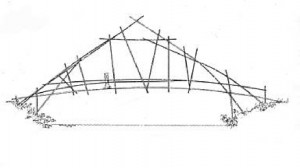

Footbridge as a twin suspended truss

Footbridge as a twin suspended truss.Footbridge as a twin suspended truss The walkway is formed by an open layer of bamboo poles and lies in the same plane as the stretcher beams. The load bearing structure lies partially above and partially below the stretcher beams. The topmost triangle consisting of compression member and brace ends provide a stiffening effect in the longitudinal axis. The braces carry a layer of bamboo joists.

Covered bridge by Jörg Stamm

Covered bridge by Jörg Stamm. This bridge is an example for constructional timber protection. The bamboo elements are not longer exposed to the weather which extend their life span.